Boiler Steelvirgamet.com: Strength Insights

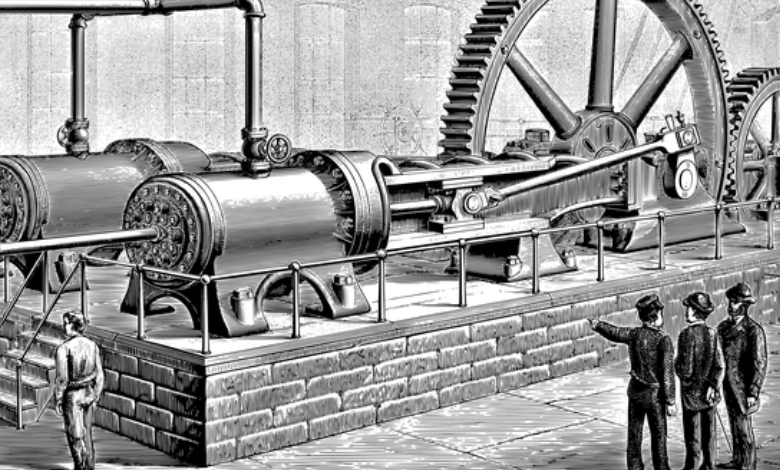

Boiler Steelvirgamet.com incredible strength and durability which can handle industrial boilers withstand extreme temperatures and pressures. Have you ever wondered what makes those towering power plants and industrial boilers withstand extreme temperatures and pressures?

In this blog post, we will explore the fascinating properties, types, applications, and benefits of using boiler steel in various industries.

Whether you’re an engineer looking for insights or a curious mind seeking knowledge, join us on this journey as we unravel the secrets behind boiler steelvirgamet.com

Properties of Boiler Steel

Boiler steel is a specialized type of steel that is designed to withstand high temperatures and pressures, making it ideal for use in boilers and other pressure vessels. One of the key properties of boiler steel is its exceptional strength. This allows it to handle the intense heat and pressure that boilers generate without deforming or cracking.

In addition to its strength, boiler steel also possesses excellent corrosion resistance. This ensures that it can withstand exposure to water, steam, and other corrosive substances commonly found in boiler systems. The corrosion resistance of boiler steel helps extend the lifespan of boilers by preventing rusting and deterioration over time.

Another important property of boiler steel is its ability to maintain its mechanical properties even at elevated temperatures. This means that it remains strong and stable even when exposed to extreme heat during operation. This thermal stability enables boilers made from boiler steel to operate efficiently and reliably for extended periods.

Furthermore, Boiler Steelvirgamet.com has good weldability, which makes it easier for manufacturers to fabricate complex shapes such as tubes, pipes, and plates for various types of boilers. It also offers good machinability, allowing for easy cutting, drilling, and shaping during the manufacturing process.

Types of Boiler Steel

When it comes to choosing the right boiler steel for your application, understanding the different types available is crucial. Each type of boiler steel has its own unique properties and characteristics that make it suitable for specific uses.

One common type of boiler steel is carbon steel. It contains varying amounts of carbon, which gives it excellent strength and durability. Carbon steel is widely used in boilers due to its high thermal conductivity and resistance to corrosion.

Another type is alloy steel, which consists of various elements such as chromium, nickel, and molybdenum. These alloying elements enhance the mechanical properties of the steel, making it more resistant to high temperatures and pressure.

Stainless steel is also commonly used in boilers because of its exceptional corrosion resistance. It contains a minimum of 10% chromium, which forms a protective layer on the surface that prevents oxidation.

Additionally, there are specialized grades such as heat-resistant steels designed specifically for use in high-temperature environments. These steels retain their strength even at elevated temperatures and are often used in power plants and industrial furnaces.

The choice between these types depends on factors like operating conditions, required strength levels, cost considerations, and maintenance requirements. Consulting with experts can help you determine the most suitable type for your specific needs.

Applications of Boiler Steelvirgamet.com

Boiler Steelvirgamet.com is widely used in various industries due to its exceptional strength and durability. Its unique properties make it a suitable choice for a wide range of applications.

One of the primary applications of boiler steel is in the construction of boilers, which are essential components in power plants and industrial facilities. Boiler steel’s high tensile strength and resistance to corrosion make it ideal for handling high-pressure steam and hot water. It ensures the safe and efficient operation of these critical systems.

Another common application is in the manufacturing of pressure vessels. These vessels are used to store gases or liquids at high pressures, such as compressed air tanks, gas cylinders, or storage tanks for chemicals. The superior toughness and weldability of boiler steel ensure that these pressure vessels can withstand extreme conditions without compromising safety.

Furthermore, boiler steel finds its use in heat exchangers, which play a crucial role in many industrial processes like chemical production or HVAC systems. Heat exchangers transfer thermal energy between fluids while maintaining their separation. The excellent thermal conductivity and stability make boiler steel an ideal material for this purpose.

Moreover, Boiler Steelvirgamet.com is also utilized in the fabrication of pipes that carry fluids under high temperatures and pressures. Whether it’s transporting steam, oil, gas, or other substances at extreme conditions – boiler steels’ resilience guarantees a reliable performance over extended periods.

Benefits of using Boiler Steelvirgamet.com

Boiler steel is a type of carbon steel that is specifically designed for use in the construction of boilers and pressure vessels. It offers a range of benefits that make it an ideal choice for these applications.

One of the key advantages of boiler steel is its high strength. This ensures that the material can withstand the extreme pressures and temperatures inside boilers without deforming or failing. The strength also allows for thinner walls, which reduces weight and cost while maintaining structural integrity.

Another benefit is the excellent corrosion resistance of boiler steel. This makes it highly resistant to rust and other forms of degradation, even when exposed to harsh conditions such as high humidity or corrosive substances. The corrosion resistance helps prolong the lifespan of boilers, reducing maintenance costs and downtime.

Boiler steel also exhibits good weldability, which means it can be easily joined together using various welding techniques. This allows for efficient fabrication and installation processes, saving time and labor costs.

Furthermore, boiler steel has excellent heat conductivity properties, ensuring efficient transfer of heat from combustion gasses to water or steam within the boiler system. This results in improved energy efficiency and reduced fuel consumption.

Using boiler steel offers numerous benefits including high strength, corrosion resistance, weldability, heat conductivity – all contributing to reliable performance and cost-effectiveness in boiler applications.

Common Grades and Standards

When it comes to Boiler Steelvirgamet.com, there are several common grades and standards that you should be familiar with. These grades and standards help ensure the quality and performance of the steel used in boilers.

One commonly used grade is ASTM A516, which is a carbon steel plate designed for moderate or lower temperature service. This grade has excellent notch toughness and weldability, making it suitable for a wide range of applications.

Another commonly used grade is ASTM A387, which is a chromium-molybdenum alloy steel plate. This grade offers high tensile strength, excellent corrosion resistance, and good impact resistance at elevated temperatures.

In addition to these grades, there are also various international standards that govern the manufacturing and testing of boiler steel. Some examples include EN 10028 (European standard), ASME SA 516/ASTM A516 (American Society of Mechanical Engineers), and JIS G3103 (Japanese Industrial Standards).

It’s important to understand these grades and standards when selecting boiler steel for your application. They provide guidelines for material properties, chemical composition limits, mechanical testing requirements, heat treatment processes, and more.

Tips for Choosing the Right Boiler Steel

When it comes to choosing the right boiler steel, there are a few important factors to consider. First and foremost, you need to ensure that the steel you select is suitable for high-temperature applications. Boiler steels should have excellent strength and resistance to corrosion and oxidation.

Another crucial factor is the specific requirements of your application. Different boilers require different types of steel, depending on factors such as pressure levels and operating temperatures. Therefore, it’s essential to understand the specifications and needs of your boiler system before making a decision.

Additionally, consider the fabrication process involved in manufacturing boilers. Some steels may be easier to work with than others, so it’s important to choose a material that can be easily formed, welded or machined according to your requirements.

Furthermore, take into account any industry standards or regulations that may apply in your region. It’s crucial to choose boiler steel that meets all necessary codes and standards for safety and performance.

Conclusion

Boiler steel is an essential material in various industries, providing the strength and durability required for high-pressure and high-temperature applications. Its unique properties make it a preferred choice for boiler manufacturers and operators alike.

In this article, we have explored the properties of boiler steel, its different types, applications, benefits, and common grades and standards. From its exceptional resistance to corrosion and thermal stress to its ability to withstand extreme conditions, boiler steel ensures reliable performance in demanding environments.

When choosing the right boiler steel for your project or application, it is crucial to consider factors such as temperature range, pressure requirements, weldability, and cost-effectiveness. Consulting with experts or reputable suppliers like Virgamet.com can help you make informed decisions based on your specific needs.