Industrial machinery installation is a critical aspect of setting up any manufacturing or production facility. Proper installation not only ensures the machinery operates effectively but also guarantees the safety of workers and optimizes long-term performance. This article covers the essential steps, best practices, and safety protocols for Industrial Machinery Installation.

Understanding the Importance of Industrial Machinery Installation

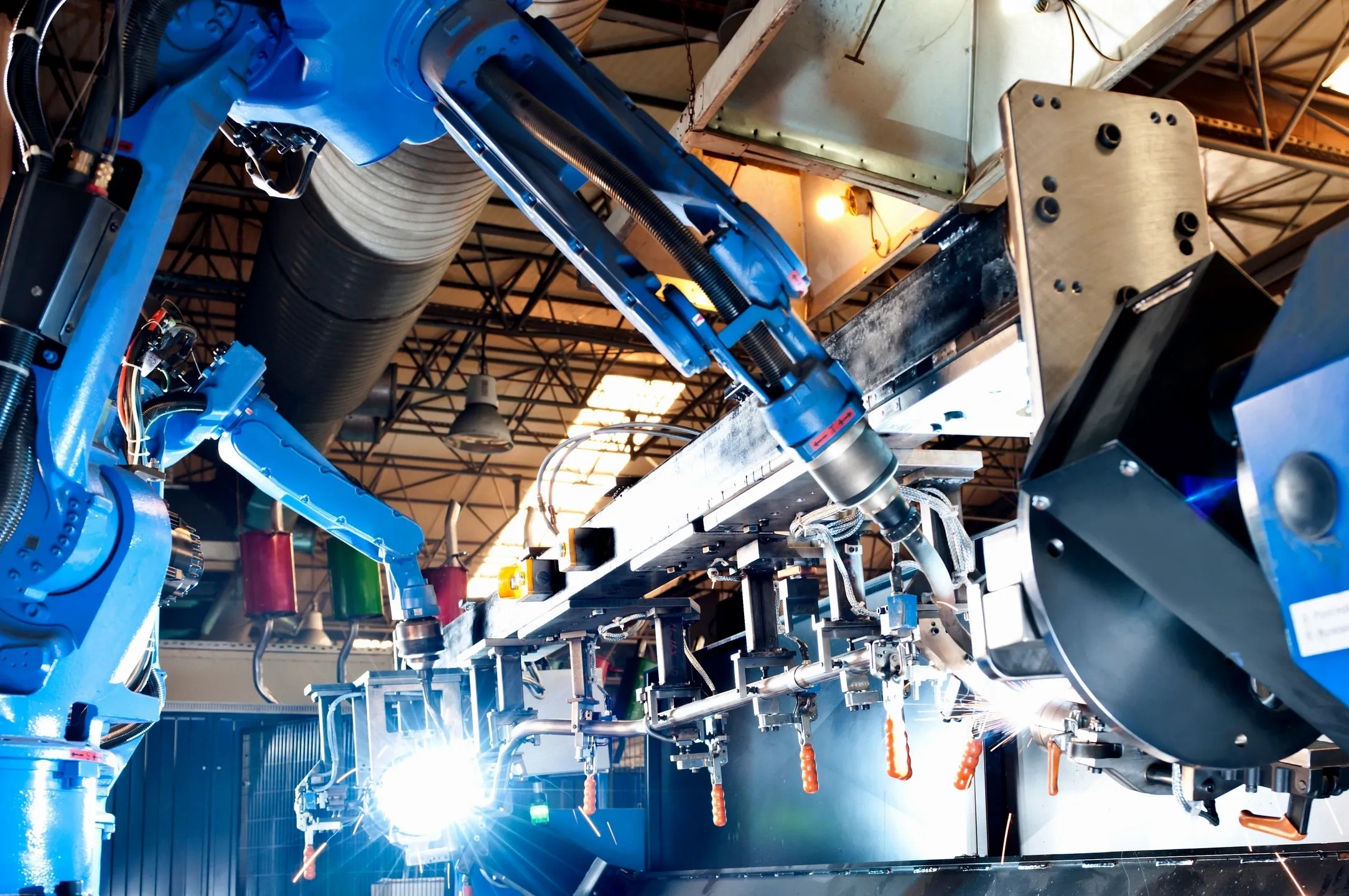

The installation of industrial machinery is not merely about placing equipment on the floor and connecting it to power. It involves a well-planned process that includes site preparation, proper equipment handling, and precise installation procedures to maximize efficiency, reduce downtime, and minimize the risk of equipment failure. Whether installing a large industrial press, conveyor system, or automated production line, attention to detail during installation is paramount to achieving optimal results.

Site Preparation for Machinery Installation

Before the machinery can be installed, it’s essential to prepare the site. This preparation is critical for creating a stable environment that will support the machinery’s operation for years to come.

Assessing the Facility Layout

An effective layout plan ensures that the machinery fits within the designated space while allowing for easy access to maintenance areas. Engineers should consider factors such as workflow, worker safety, and future expansion when designing the layout.

Ensuring Structural Integrity

Industrial machinery can be heavy, and improper installation can lead to structural damage. It’s essential to ensure that the floor and building structure can support the weight of the equipment. Concrete floors should be reinforced where necessary, and load-bearing calculations should be made to ensure stability.

Addressing Electrical and Power Requirements

Industrial machinery often requires specialized electrical configurations. Properly installing electrical systems to support the machinery’s needs is crucial. It’s important to plan the installation of power supply lines, grounding systems, and emergency power backups. Additionally, coordination with local utility providers may be necessary to ensure adequate power delivery.

The Machinery Installation Process: Steps for Success

The machinery installation process must be precise, following a series of steps to ensure safety and efficiency.

Unpacking and Inspection

Upon delivery, the machinery should be thoroughly inspected to ensure no damage occurred during shipping. Inspect each component and verify the equipment specifications to ensure that everything matches the order.

Positioning the Machinery

Positioning the machinery involves placing it in the predetermined location, ensuring it aligns with the design layout. The machinery should be placed on level surfaces, and alignment checks must be done to guarantee that it’s straight and stable.

Securing the Equipment

Once positioned, the machinery must be secured to prevent movement during operation. Bolts, anchors, and fasteners should be used according to the manufacturer’s specifications. These ensure that the equipment remains stable, even under the stresses of heavy operations.

Installing Mechanical Connections

Mechanical connections, such as belts, chains, and gears, should be installed carefully. Any misalignment at this stage can lead to excessive wear or operational inefficiencies. It’s essential to follow the manufacturer’s instructions and use the correct tools for precise installation.

Electrical and Wiring Setup

Proper wiring of industrial machinery ensures its safe operation. Electrical connections should be handled by licensed professionals who can safely connect the equipment to power sources and install necessary control systems. It’s important to follow national and local electrical codes to prevent accidents.

Best Practices for a Successful Industrial Machinery Installation

To guarantee the best possible outcome, it’s important to follow certain best practices throughout the installation process.

Work with Experienced Professionals

Engage qualified and experienced machinery installers and engineers. Their expertise ensures that the installation is performed to the highest standards, minimizing errors and delays. It’s advisable to hire professionals familiar with the specific type of machinery being installed.

Use Proper Tools and Equipment

Using the correct tools is essential for proper machinery installation. Specialized tools ensure precision, while high-quality equipment prevents damage to components during handling and assembly. It’s also important to have a range of tools on hand for unexpected challenges.

Safety Protocols for Industrial Machinery Installation

Safety should always be a top priority when installing industrial machinery. Following proper safety protocols helps prevent accidents and protects workers from harm.

Conduct a Risk Assessment

Before starting the installation, a comprehensive risk assessment should be conducted. Identify any hazards, such as electrical risks, moving parts, or high temperatures, and take appropriate measures to mitigate these risks. This includes setting up proper safety barriers, providing workers with personal protective equipment (PPE), and ensuring proper machine guarding.

Train Employees

Only trained personnel should be allowed to handle machinery installation tasks. Proper training ensures that employees understand the safety protocols and installation procedures. Additionally, workers should be informed about emergency shutdown procedures and how to handle hazardous situations.

Maintenance Considerations After Installation

After the industrial machinery is installed, maintenance is essential for ensuring its longevity and preventing unexpected breakdowns.

Develop a Maintenance Schedule

Establish a comprehensive maintenance schedule for each piece of machinery. Routine checks, lubrication, cleaning, and adjustments should be part of the regular upkeep to prevent wear and ensure smooth operation.

Keep Spare Parts on Hand

Keeping spare parts available for quick replacement can minimize downtime in case of machinery failure. Ensure that critical components like bearings, belts, and filters are readily available for fast replacement.

Conclusion

Industrial machinery installation is a complex and essential process that requires careful planning, expert execution, and a strong focus on safety. By following best practices, ensuring proper site preparation, and adhering to safety protocols, businesses can ensure that their machinery operates efficiently and safely for years to come. A successful installation not only helps maximize productivity but also reduces downtime and maintenance costs, ultimately contributing to the company’s overall success.